A Work In Progress. Please add your symptoms and photos below.

| Problem | Solution | Comments |

|---|

| First Layer Adhesion - poor adhesion on your first layer, characterized by blobs of hot plastic and cursing | - See 3D Printing Material - FDM for the ideal bed surface for your filament.

- (re)Apply hair spray or glue stick

- Increase the height of your first layer only

- Add structure to your print to enhance adhesion, such as brim

- Check the nozzle clearance when homed on the z-axis. Most printers should be between 0.006 and 0.010 inches.

| Please request assistance if the printer must be adjusted. |

| Adhesion - Print comes loose from the print bed | - See 3D Printing Material - FDM for the ideal bed surface for your filament.

- (re)Apply hair spray or glue stick

- Add structure to your print to enhance adhesion, such as brim

- For some materials, like ABS, you may need to disable the parts cooling fan in your slicer settings

| Please request assistance if the printer must be adjusted. |

| Elephant foot - print lifts at the corners | See Adhesion |

|

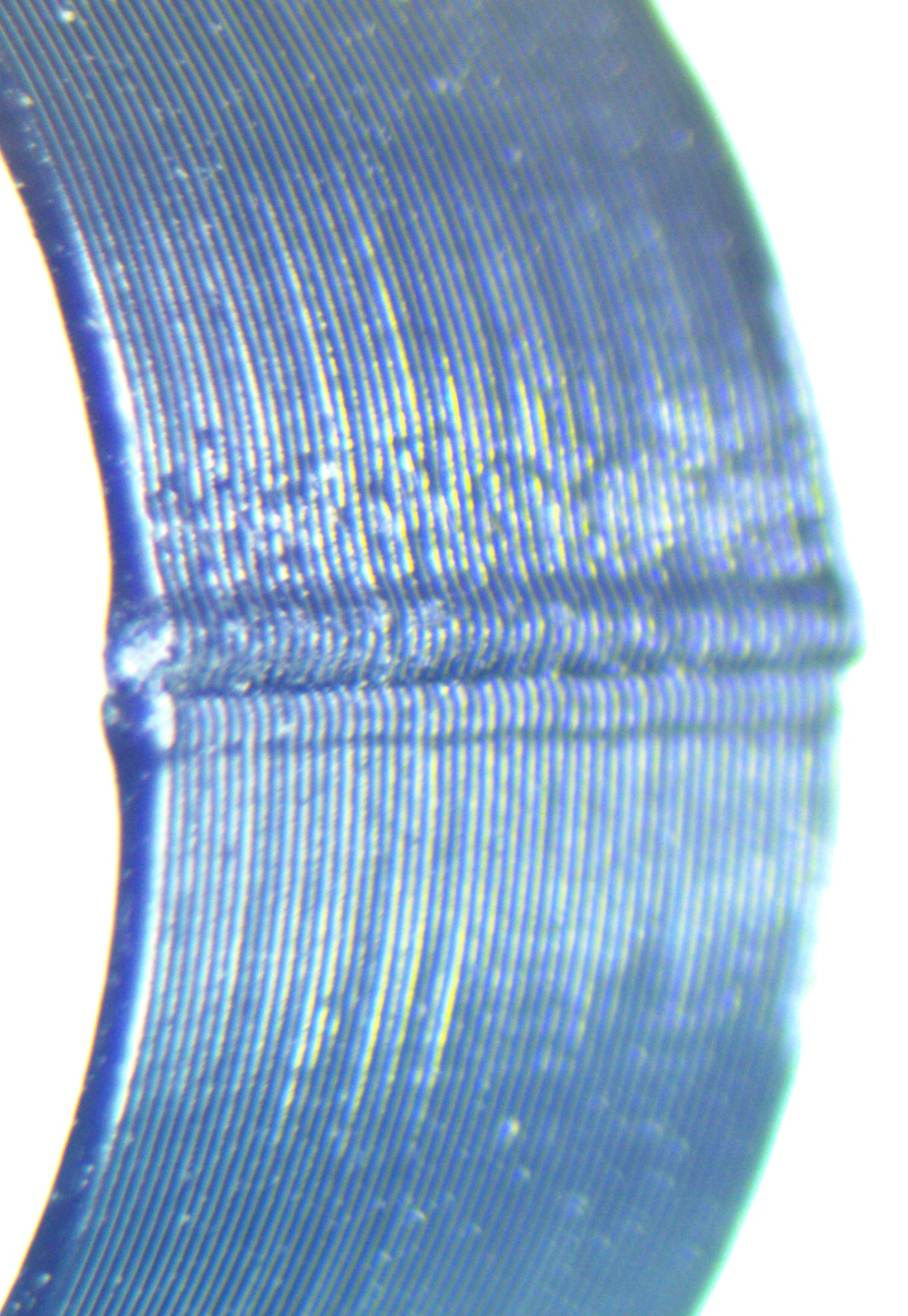

| Underextrusion - parts are printing with too little plastic | - Double-check your extrusion settings in your slicer

- Do a "cold pull" to clear the nozzle

| Please request assistance if a cold pull does not clear the blockage. |

| How to Remove Z-Seam | https://3dprintguides.com/2020/06/how-to-remove-z-seam-3d-print/ |

|

| Adjust Retraction Speed and Distance | https://3dprintguides.com/2020/02/best-retraction-settings-to-avoid-stringing/ |

|

Cold Pull

A cold pull works by pulling semi-soft material back through the nozzle, along with any debris clogging the nozzle. It works best with slipper, soft materials like nylon. Special cleaning filament can be used to clean the nozzles on a regular basis.

- Heat the hotend up to the working temperature of the filament to be used

- Push the filament through the hot end until the previous material is cleaned out

- Let the hotend cool

- Heat it again to 110°C and pull on the filament while holding the extruder release until the filament comes out.

- Cut off the melted end and repeat until it comes out clean and the nozzle is clear

- Typically only a couple of cycles are needed

Resources

See the following links for more help.

PrintaGuide - one of the best 3D print quality guides on the interwebs.